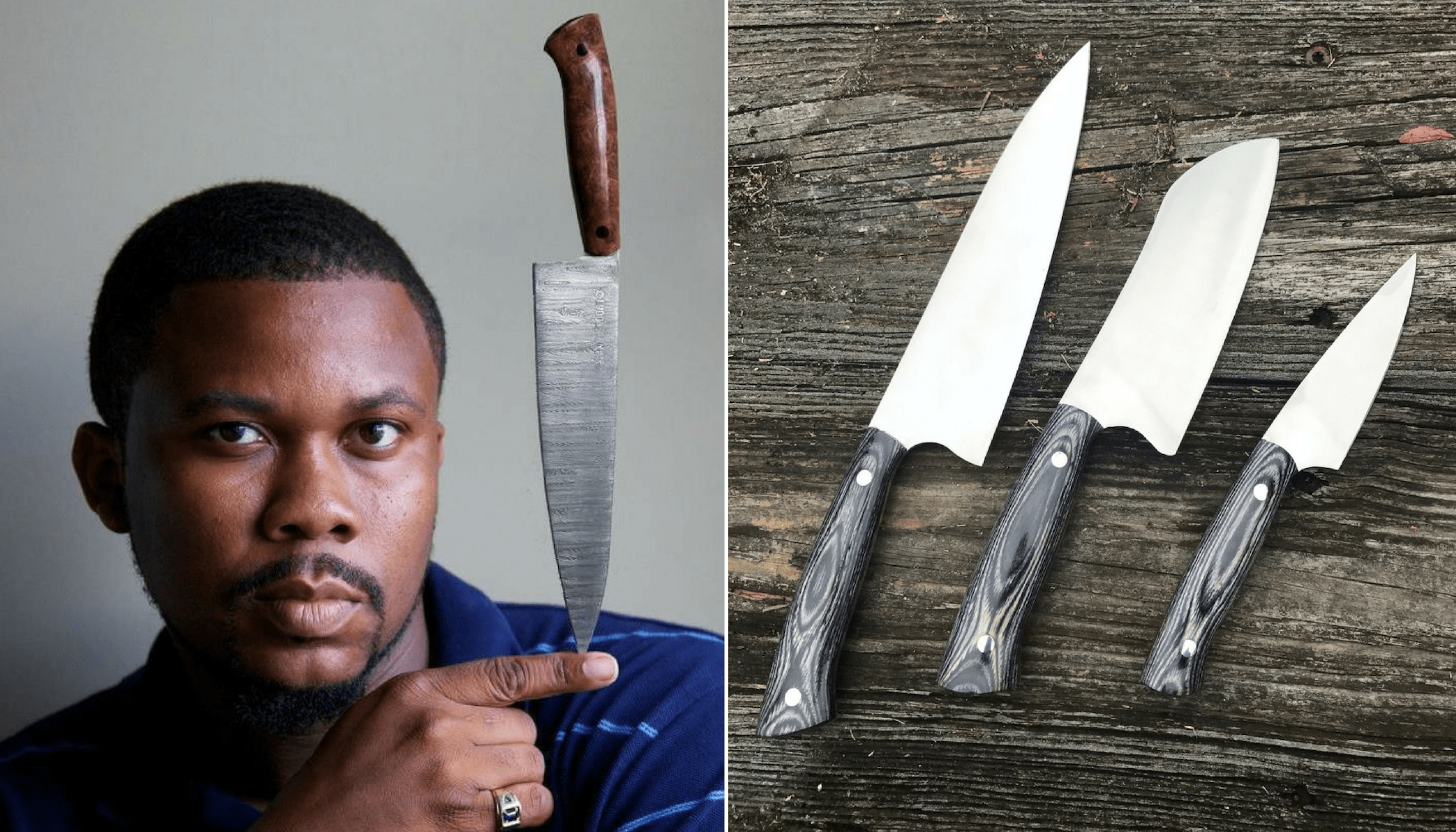

Chefs love their knives. They protect them, care for them, and keep them close at all times. But, you know who loves knives more than cooks? Knifemakers. True hand-made knives are a rarity, and in America, there are only a handful of bladesmiths who deal with them. Quintin Middleton of St. Stephen, South Carolina is one of them. His company is Middleton Made Knives. Francis Lam talked with Middleton about the craft of knifemaking, and how he creates knife designs specifically with chefs in mind. See more images of Middleton's beautiful knives at Middleton Made Knives Instagram.

Francis Lam: When did you decide you wanted to become a knife maker?

Quintin Middleton: When I decided to be a knifer maker, man, it was just one magical moment in life where I decided, yes, I want to do this. It was is when I watched Conan the Barbarian. [Francis laughs] Man, quit laughing at my dreams. This is my life! [laughs]

FL: No, I'm very serious. Conan, Arnold Schwarzenegger with long hair.

QM: I watched the movie and it was like this aha moment. I wanted to be Conan. After the movie went off, I took tubing off my swing set, I got a cinder block and a hammer, I flattened the tubing and I'm running around chasing my brothers like this is my sword. After that you couldn’t stop me from making bow and arrows and aluminum swords and things like that. That's where the passion really started.

FL: How old were you?

QM: When Conan came on TV I was probably six or seven or something like that.

FL: As a six- or seven-year old, you went out and you took apart your swing set and just started banging a sword out of it. That's incredible.

QM: Trust me, I got in trouble.

FL: So, you went from having these alarmingly real toy swords you were making to eventually got into the craft of making real knives. I don't know much about this world, but I understand most artisan knife makers mostly make weapons, right? Like swords, hunting knives – weapons. How did you get into making chef's knives?

QM: My mentor Jason Knight taught me how to make hunting knives and swords and I was making that for a long time. And I had a dream; Jesus came to me in a dream saying make chef knives. It was like I was at a crossroad. After I got that idea of making chef knives, I made a long list of every top chef in Charleston, South Carolina. I called every last one of them, and every last one of them turned me down. I guess I was just this telemarketer calling them, trying to sell a knife. I was so disappointed that nobody will buy a knife from me.

After I hung up and waited a few hours that same feeling or notion came back on me saying to call one individual back. His name is Craig Deihl; he was the executive chef for Cypress. I asked him, “Can you help me develop a knife?” I took what I thought were the ideal chef knives to his restaurant, took them to his sous chefs and chef de cuisine and let them try and see what they think. No one bought it. Craig basically gave me that tough love. He said these are nice, these are cool. But this is too heavy. This is too thick. This is basically an axe. It was something that I don't want to hear, but something that I needed. He gave me hints or tips saying to make this knife longer or thinner or taller, things like that. And from those tips I made knives that he would like. He told his friends, they told their friends, and now we’re on The Splendid Table talking.

FL: At this point you've been making knives chefs do love for years now. How do you design a new knife? Aside from the quality of the blade, which we’ll get to later, what makes a knife good?

QM: Craig Deihl and his sous chef Bob Cook, they were very instrumental in this. I would spend hours in their kitchen. I'm watching how they hold themselves and how they hold their knives. My mind is just racing and saying, what will make their job easier? If you're using this knife six to eight hours a day, what can I do to improve on what you have now? It took a few years to get it right, to what I think is the ideal knife. I researched Japanese knives and German knives and French knives, and picked from each culture from the literal research and practical research from me watching and trial and error; that got me to the point to where I am now.

FL: When you were watching those cooks and you were asking how can I make your life easier, what are some things you were thinking about? What were you looking at?

QM: Some of the knives that they're using are kind of heavy. I want you to use the knife instead of it using you. Like it's an extension of your arm. If you take your arm out and point your finger, you wouldn't think my finger is heavy. It’s a part of you, so it feels natural. Coming from that notion now I know I need to make a knife light. What are the knives that people like? They like Japanese knives. The profile of my knives are Japanese-ish. And I took the European handle. My mentor makes this type of handle that is almost like a Coke bottle that he got from the Filipino machete. I've copied that handle shape for so long, so I put that on my knife. And now I have this little notch on the chef's knife where when you do a pinch grip on your knife your middle finger sits in that area. It feels comfortable. It's very simple, but when you grab it you’re like, “Oh, he really thought this out.”

FL: As I understand it, you had to pass this wild sounding knife maker test to test the quality of blades. Tell us about that test.

QM: I was a part of this organization called the ABS, the American Bladesmith Society. It’s an organization that teaches people how to be knife makers or bladesmiths. There are different categories; you have your apprentice smiths, your journeyman smiths and your master smith. To get to the next level, you have to do a series of test. You have to forge a ten-inch long blade, so overall a fifteen-inch knife. And you have to chop through a two-by-four twice and still have a sharp enough edge to shave the hair on your arm. Cut through a one-inch Manila rope. And put that knife in a vice and bend it 90 degrees without breaking.

FL: That’s bananas. Your knives can do that?

QM: Well, that's the standard that I’m going for. Yes. But I don't suggest it right, because that voids your warranty. [both laughing] But you can buy another one.

FL: When I hear you describe that test and the quality of blades, it sounds so high tech where you have to have the most high tech equipment to make that stuff. But I saw a video of you working, and it was literally in your backyard. You were taking this piece of metal out of a fire and hammering it with a hammer. It was definitely a Conan vibe. Do you still make every knife yourself by hand like that?

QM: Yes, every knife that comes out of my shop that says Middleton Made Knives is handmade by me and my crew.

FL: The two people you're working with are obviously a small crew, but you're also in a really small town. It reminds me of the legendary stories of Japanese knife makers in Sakai and places in Japan where it’s a small village, but that village becomes known for doing this thing. Is that something that goes through your mind at all?

QM: Definitely. My dream from day one was I wanted to build a factory and employ people from my community; that was my dream from the start. Even when I was making knives, a lot of the people that I looked up to were kind of disappointed that I was going into the production knife realm. They say, “You have so much potential and you have so much to give. You have it.” But Mister Ford and the Dodge Brothers and whoever made the BMW, they all started in someone’s garage or backyard. In my mind I'm saying, why can't it start with me? I have the drive, I have the determination. Why not? I can do it. I've been making knives for 16 years and my company has been open almost nine years. It’s going in the right direction. I'm blessed. I’m good.

Before you go...

Each week, The Splendid Table brings you stories that expand your world view, inspire you to try something new, and show how food connects us all. We rely on your generous support. For as little as $5 a month, you can have a lasting impact on The Splendid Table. And, when you donate, you’ll join a community of like-minded individuals who love good food, good conversation, and kitchen companionship. Show your love for The Splendid Table with a gift today.

Thank you for your support.

Donate today for as little as $5.00 a month. Your gift only takes a few minutes and has a lasting impact on The Splendid Table and you'll be welcomed into The Splendid Table Co-op.